PEMP Generator Parts Store

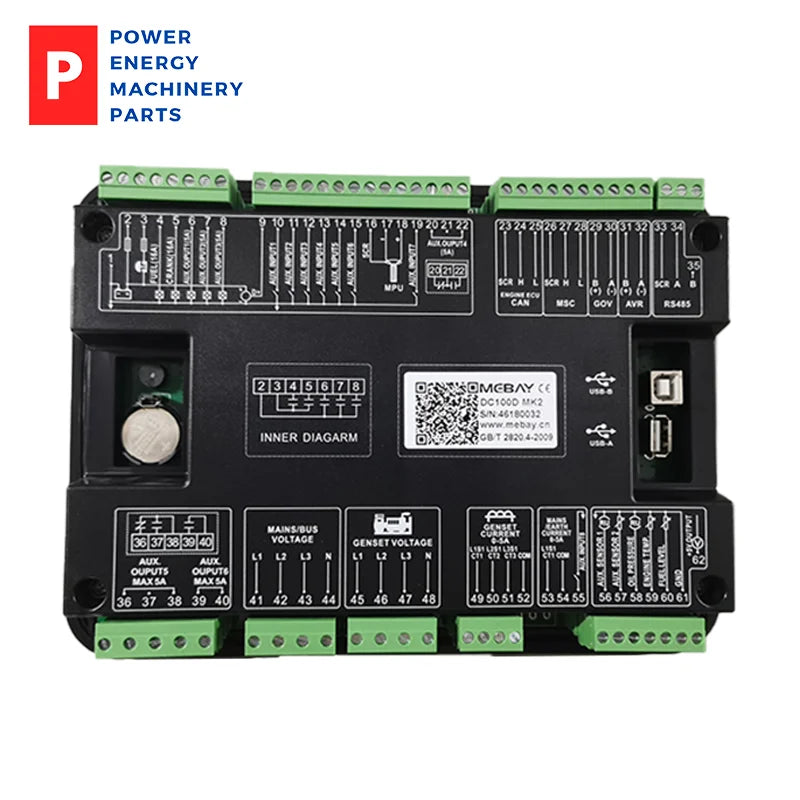

Original DC100D Mebay Generador Parts Parallel Controller Diesel Generator Engine LCD Control Board CAN Communication Interface

Original DC100D Mebay Generador Parts Parallel Controller Diesel Generator Engine LCD Control Board CAN Communication Interface

Couldn't load pickup availability

Original DC100D Mebay Generador Parts Parallel Controller Diesel Generator Engine LCD Control Board CAN Communication Interface

This series of controllers is designed for manual/automatic parallel systems of multiple generator sets of the same capacity or different capacities. It is also suitable for constant power output of a single generator set and parallel generation of multiple generators. The generator set has automatic start and stop/parallel operation, data measurement, and alarm protection functions.

This controller uses a 4.3-inch TFT color large-screen LCD to display relevant parameters of the generator set. It has a new and original UI design. The parameters are displayed through analog pointers and numbers. The LCD screen can display multiple current fault states at the same time, and can effectively implement protective shutdown when the generator set is not working properly.

The parallel controller has the function of controlling GOV and AVR, can automatically synchronize and load share, and can be connected in parallel with the generator set equipped with DC100D controller. The controller accurately monitors the various working conditions of the generator set. When the generator set is working abnormally, it will automatically open and detach from the busbar, shut down the generator set, and display the fault status on the LCD. The controller has a SAE J1939 interface and can communicate with a variety of EFI engine ECUs with J1939 interfaces.

The controller has built-in simplified Chinese, traditional Chinese, English, Spanish, and Russian display interfaces to choose from, and the language interface can be customized according to customer requirements. All parameters of the controller can be adjusted through the buttons on the controller panel, or adjusted and monitored using a PC through the USB port or RS485 interface. It can be widely used in various types of generator set automation systems.

Specifications

project

Parameters

Operating Voltage

DC9V to 36V continuous power supply

Machine power consumption

Standby: 24V: MAX 2W

Operation: 24V: MAX 5W

AC voltage input

One phase two wires 30VAC-276VAC (ph-N)

Two-phase three-wire 30VAC-276VAC (ph-N)

Three-phase four-wire 30VAC-276VAC (ph-N)

Engine speed signal range

200-10000Hz

Maximum cumulative running time

99999.9 hours (minimum storage time 6 minutes)

fuel output

Max 16Amp DC+VE supply voltage output

Motor output

Max 16Amp DC+VE supply voltage output

Configurable relay 1

Max 5Amp DC+VE supply voltage output

Configurable relay 2

Max 5Amp DC+VE supply voltage output

Configurable relay 3

Max 5Amp DC+VE supply voltage output

Configurable relay 4

Max 5Amp/250V passive contact normally open-normally closed output

Configurable relay 5

Max 5Amp/250V passive contact normally open-normally closed output

Configurable relay 6

Max 5Amp/250V passive contact normally open output

Excitation output

Maximum 0.9Amp DC+VE supply voltage output

Switch input

Effective when connected to the negative pole of the battery

working conditions

-30-70℃

storage conditions

-40-85℃

Protection level

IP54: When a waterproof ring is installed between the controller and the control panel.

Insulation level

When AC2.2kV voltage is applied between the AC high-voltage terminal and the low-voltage terminal, the leakage current shall not exceed 3mA within 1 minute.

Dimensions

241mm*177mm*45mm

Hole Size

220mm*160mm

weight

1Kg

Share